Risk assessments are essential in chemicals management to minimise risk to human health. They are an evaluation of the possible ways a hazard may present itself to cause harm, and are key in any workplace where physical, chemical, or other occupational hazards may be present.

A risk assessment can be used to determine:

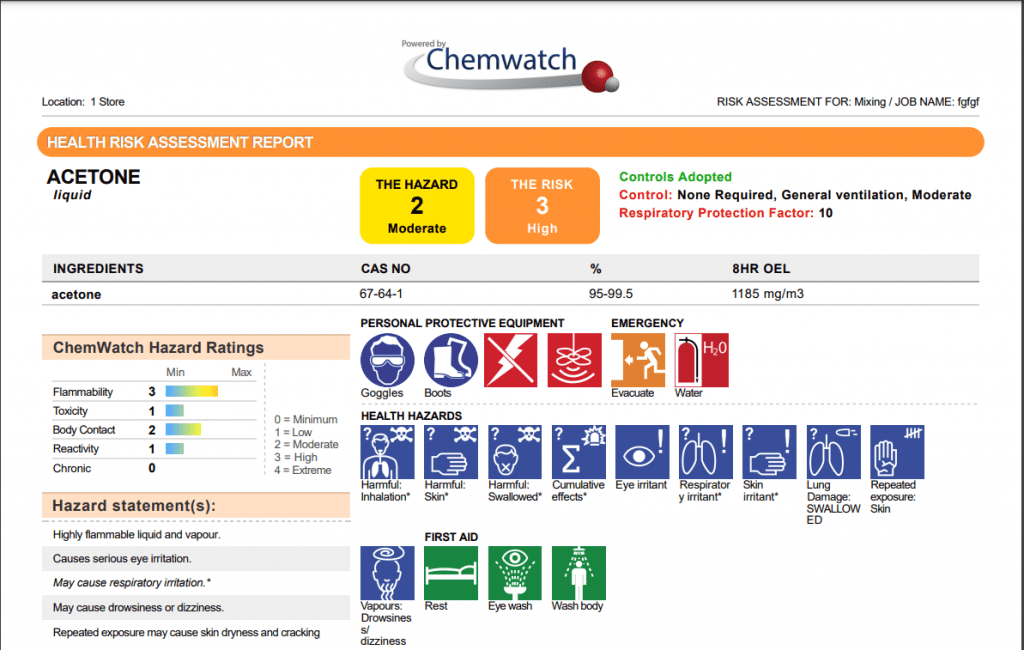

Chemwatch's powerful software takes the hard work out of Risk Assessment generation. It automatically reads the SDS of your chemical and calculates risk factors based on your task, combining risk controls into a succinct and readable one-page document. Our assessment includes hazard statements, classification information, risk controls, and thorough personal protective equipment (PPE) recommendations. Keep reading to understand the importance of risk assessments and how to conduct one for your workplace

The term risk and hazard are often used interchangeably, however they have quite different meanings. According to the Globally Harmonised System of Classification and Labelling of Chemicals (GHS), a hazard is any source of potential damage, harm, or adverse health effects on something or someone. Risk is the probability and degree to which a person will be harmed or experience adverse health effects as a result of exposure to a hazard.

Factors that influence risk include: how much a person is exposed to a hazard; how the person is exposed (inhalation, ingestion, skin contact, etc.); and how severe the effects of the hazard exposure is in the given conditions. Because handling and storing chemicals carries innate risk, our goal is to help employers and employees find cost-effective solutions to control risks in their workplace to the benefit of all involved.

A risk assessment is the key to managing occupational health and safety in any enterprise where chemicals are handled. It allows employers and businesses to be proactive in identifying hazards and taking action to minimise the probability of risk before an incident occurs.

The Australian Work Health and Safety Act 2011 (WHS Act) states that the key to good risk assessment is to determine what hazard and risk controls are ‘reasonably practical’. This includes determining the likelihood and degree of harm, as well as assessing the availability and suitability of risk controls. The most effective way to mitigate a risk is to remove it entirely, however this is not always possible—especially in the chemicals industry.

While you may only have one SDS for a given product, you may need multiple risk assessments depending on the tasks required. For example, transferring acetone from one vessel to another has very different hazards to spraying acetone onto a surface.

Risk assessments are a necessary and ongoing process when working with chemicals, as well as any other hazardous materials or conditions. A risk assessment should be undertaken when there are changes at a workplace which may present a new or unknown risk, or impact the effectiveness of existing risk control measures. It is also important to assess compounded risks if a work activity combines a number of hazards. A risk assessment should determine the cause of the risk and what reasonable controls can be implemented to minimise risk.

The 2011 WHS Act explains that the duty of care for risk management lies in part with persons conducting a business or undertaking (PCBUs) and workplace officers, as well as importers, manufacturers, and suppliers of substances. Assessing risks should include the involvement of workers to decide what controls are reasonably practical. Workers also have a duty to take care of their personal safety and not take any unnecessary risks.

A stepwise guide to creating a risk assessment in your Chemwatch system can be found in our webinar of this same topic. It is also outlined in the Risk Assessment eLearning module in the Chemwatch portal.

The Risk Assessment module is available as an option in our GoldFFX, Chemeritus, and COSHH COBRA packages.The module is based on International Labour Organisation (ILO) and United Nations (UN) guidelines, and allows employers and employees alike to generate a risk assessment with ease. It is designed for small and medium enterprises and eliminates expertise as a factor so that anybody can generate and communicate risk assessments and controls.

All you need is the SDS or label and working conditions. Conditions include the type of task, working temperature, substance dustiness or volatility at that temperature, and scale and frequency of chemical use in the given task. Our software can then generate a risk assessment, complete with identified control bands and written guidance for controlling risk in the specified task—including precautionary statements, controls, and PPE suggestions, as well as optional Approvals information.

Our database of SDS allows almost all risk assessments to be pre-populated through SDS data extraction. Data points include: ingredients, proportions, CAS numbers, physical and chemical properties, GHS classifications, and precautionary statements and pictograms. If data is not available, you can request a member of the Chemwatch team to extract it for you, or you can extract it yourself. From these, our program generates a complete risk assessment report for you, in as little as 30 seconds.

Chemwatch Risk Assessment reports are compliant to ILO and UN models for human health and safety. The one-page reports provide advice for usage, handling, transportation, and storage, as per the classification on the product label or SDS. Chemwatch health risk assessment reports contain icons, pictograms, clear and concise phrases, as well as colour coded hazard and risk statements to ensure easy and succinct communication.

The risk assessment process is informed by the ILO’s control banding model, which minimises the subjectivity of risk and maximises the controls to protect employee health. It assigns certain control measures to certain chemicals which encompass all of the required risk controls based on GHS hazard classification. COSHH (control of substances hazardous to health) Essentials has refined these control bands even further to maintain business compliance in the United Kingdom, and Chemwatch’s system is compliant in the many regions which use control banding as their choice assessment tool.

If you have any questions about the Risk Assessment module, talk to the Chemwatch team today. We’re informed by over 30 years of chemical expertise and well equipped to help you with evaluation of risks. We also have a library of past webinars covering global safety regulations, software training, accredited courses, and labelling requirements. Keep an eye on our Webinar calendar for upcoming Webinars, Mini Briefs and ChemXpress training videos.

Sources: