Occupational hazards are everywhere in the chemicals industry, however some substances pose more of a threat than others. Mitigating risk is key, and this is where exposure limits play their important role.

In general, the occupational exposure limit (OEL) indicates the level of admissible exposure, for a length of time (usually 8 hours), to a chemical or physical hazard that is not likely to affect the health of a worker. The OELs for chemical substances are established based on the chemical properties of the substance, experimental studies on animals and humans, and toxicological and epidemiological data

The aim of the exposure limit is to minimise any health or safety hazards that come with being exposed to the substance. These limits can vary between jurisdictions, so it is important to understand the meaning of this metric and the necessity of relevant OELs in any Safety Data Sheet (SDS) and Chemical Risk Assessment.

Chemical exposures can occur anywhere in almost any workplace. Everyday substances including glues, printing inks, cleaning fluids, fertilisers, and pesticides may contain hazardous chemicals which can cause physiological harm to anyone exposed to it. Exposure limits dictate the maximum level of exposure considered to be safe.

There are different measures of exposure limits depending on the jurisdiction, the type and phase (solid, gas, or liquid) of chemical present, and the physical work environment. Exposure to chemicals may occur through inhalation, ingestion, or skin contact, though many exposure limits are primarily concerned with inhalation of dusts and vapours.

An individual who works in chemical manufacturing may have more frequent exposure to hazardous chemicals as part of their ordinary duties than someone working as a cleaner, however the maximum exposure limit must still be observed in all cases. Monitoring is crucial to verifying that your workplace exposure hazards are under the OEL.

OELs can be found in Section 8 of a substance SDS, measured in mg/m3 or parts per million (ppm). Limit values can vary somewhat, depending on the regulatory jurisdiction of the SDS. OELs have many different names, all meaning the same thing. In the USA, they are called PEL (Permissible Exposure Limits), in Australia, WES (Workplace Exposure Standards), and in the UK, they are called WEL (Workplace Exposure Limits). OEL is used by the European Chemicals Agency.

The three most commonly used exposure limits account for whether an exposure is short-term isolated exposure, or if the exposure is ongoing over days or weeks within regular work activities.

Also known as the Threshold Limit Value or 8-hr Value, this exposure limit is calculated over an eight-hour workday or a 40-hour work week. A TWA is the upper limit of the allowable average exposure to a chemical for the period of time mentioned above. This limit is set to ensure no deleterious effects arise from the chemical exposure over a worker’s lifetime.

The STEL (sometimes called 15-min Value) describes a 15-minute time-weighted average exposure limit. The average exposure over the 15-min period must not exceed the STEL value. There are three rules for STEL:

a) STEL exposure must not be longer than 15 minutes.

b) STEL exposures must not be repeated more than four times per day.

c) There must be at least 1 hour between successive STEL exposures.

The Ceiling Value, also known as the Peak Value is the maximum allowable concentration at any given point in time. This exposure limit should never be exceeded.

Not all chemical substances have clearly defined OELs in every jurisdiction. When a substance OEL has not been formalised, chemical hazards may be given an estimated limit based on H-codes, GHS categories, toxicity data, and health outcomes.

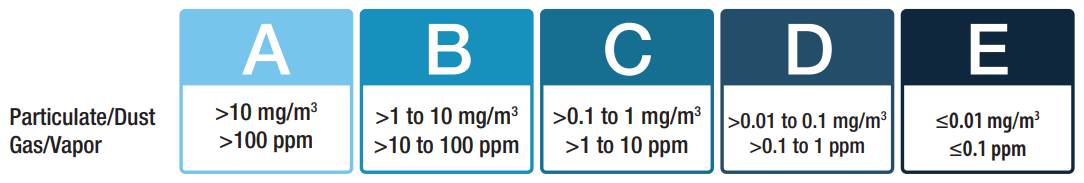

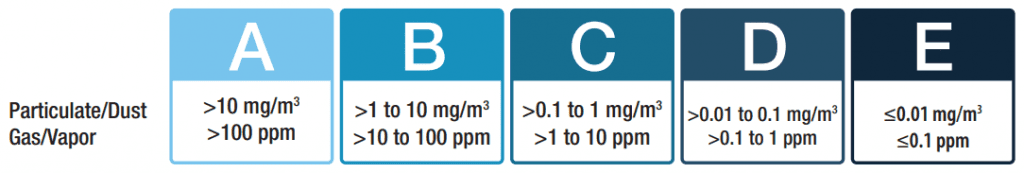

Occupational exposure banding is a process of assigning chemicals into specific categories or bands based on a chemical's potency and the adverse health outcomes associated with exposure. The output of this process is an occupational exposure band (OEB), ranging from A to E, which corresponds to a range of exposure concentrations that is expected to protect worker health.

Occupational exposure banding is a well-known method developed by the U.S. National Institute for Occupational Safety and Health (NIOSH) and it is widely used in occupational settings. Further information can be found here.

If you have any questions about occupational exposure limits, Chemical Risk Assessment, or would like advice on safely handling chemical hazards, please contact the Chemwatch team today or email sa***@*******ch.net. We’re informed by over 30 years of chemical expertise and well equipped to help you evaluate workplace risks and comply with Health and Safety regulations.

Sources: