Chemical catalysts can come in all different shapes, sizes, and forms. They are used to lower the energy threshold required to activate a chemical reaction, thereby increasing the rate—often by orders of magnitude. An estimated 90% of industrially synthesised chemicals involve some use of catalysis.

Finding the most efficient and specific catalysts is an essential part of chemical processes, and having a catalyst that is both readily available and tuneable to different reactions is ideal—this is where the zeolite family of materials shines.

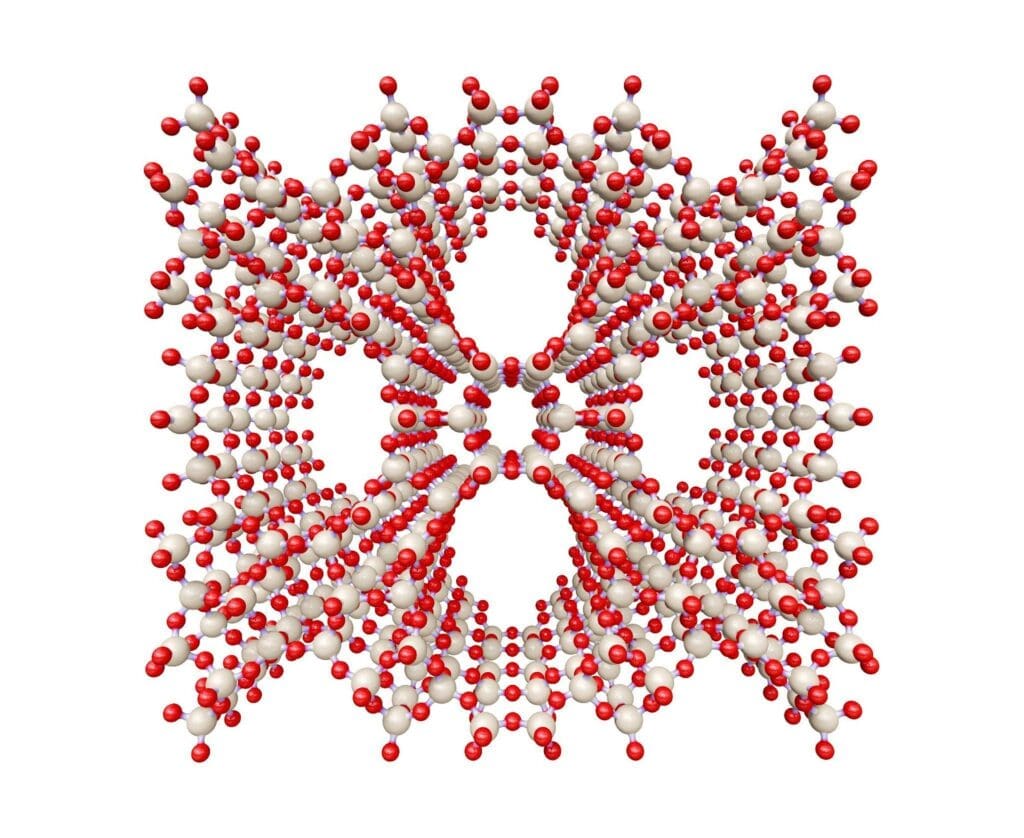

Zeolites are a class of materials with similar chemical composition and physico-chemical properties. They are usually a mixture of both silica, alumina, and water molecules, with loosely bound positive ions which can easily be exchanged for others. These positive ions, as well as the zeolites’ unique microporous structure, allows them to have widely applicable catalytic capabilities.

There are over 250 known zeolite structures, 40 of which are naturally occurring. Each unique structure receives a 3-letter designation by the International Zeolite Association Structure Commission.

The crystals form a repeating lattice structure, which can be identified and measured through crystallography. Zeolites boast extensive surface area due to their pores and can adsorb a wide variety of cations such as sodium, calcium, potassium, or magnesium. They can also adsorb hydrogen cations to function as solid acids.

The first zeolite was discovered in the 18th century when it was found that the mineral stilbite gave off significant amounts of steam when heated. This led to the understanding that water could be adsorbed to the surface of the material. Further study has identified many minerals within the family of zeolites, with many different structural configurations and pore sizes.

Zeolites are highly stable, non-toxic, reusable, and can be made from extremely abundant natural materials. Man-made zeolites can be synthesised from heating alumina and silica with sodium hydroxide, with additional template chemicals utilised to guide the structure of the crystal as it forms.

The pores of each different zeolite type can cause bonds to be broken in specific and repeatable locations, maximising the desired product and minimising any unwanted derivatives. This is particularly useful in the recycling of plastic waste, where zeolite pores can shear off specifically sized molecular pieces from the much bigger polymer, which can then be repurposed into new polymers or new materials entirely. A similar principle has been successful in transforming methane, a greenhouse gas, into methanol.

These fascinating materials also have the ability to behave as molecular sieves, filtering molecular mixtures according to the pores within the zeolite structure. This size exclusion allows for filtering and adsorbing of different molecules depending on which of the 250 zeolite structures is utilised. Man-made zeolites are usually preferred for this, as the size and shape of the crystal can be manipulated and the mineral is less likely to contain contaminants.

Despite their desirable properties, some zeolites can be difficult to work with on an industrial scale. To combat this, composite materials have been devised to maximise the benefits of the material with fewer drawbacks. Swedish scientists have developed a lightweight zeolite-foam composite, which maintains enough zeolite surface area to be useful in the selective adsorption of carbon dioxide, removing it from the atmosphere. The foam framework allows more gas to be in contact with the catalyst, as opposed to conventional zeolite powders.

Zeolites have also been used to aid water purification efforts, as the crystal can adsorb and exchange ions commonly found in hard water such as calcium and magnesium, replacing them with less harmful alternatives.

Chemwatch is backed by over 30 years of chemical expertise, boasting an extensive library of SDS and substance data. For more information on physical and chemical properties of substances, or to learn more about our services, please contact the Chemwatch team today or email sa***@*******ch.net.

Sources: