The volume of plastics in our oceans—and throughout the wider natural environment—is immense and increasing every day. With awareness rapidly spreading and potential hazards and risks being discussed more openly in the public forum, the golden question remains, what is the best way to curb this exploding environmental crisis? And as a sub-topic, how does plastic recycling really hold up?

We as a planet produce roughly 300 million tons of plastic annually, and production accounts for nearly 10% of the world’s crude oil usage. The UN’s Plastic Disclosure Project estimates that 33% of all manufactured plastic is only used once.

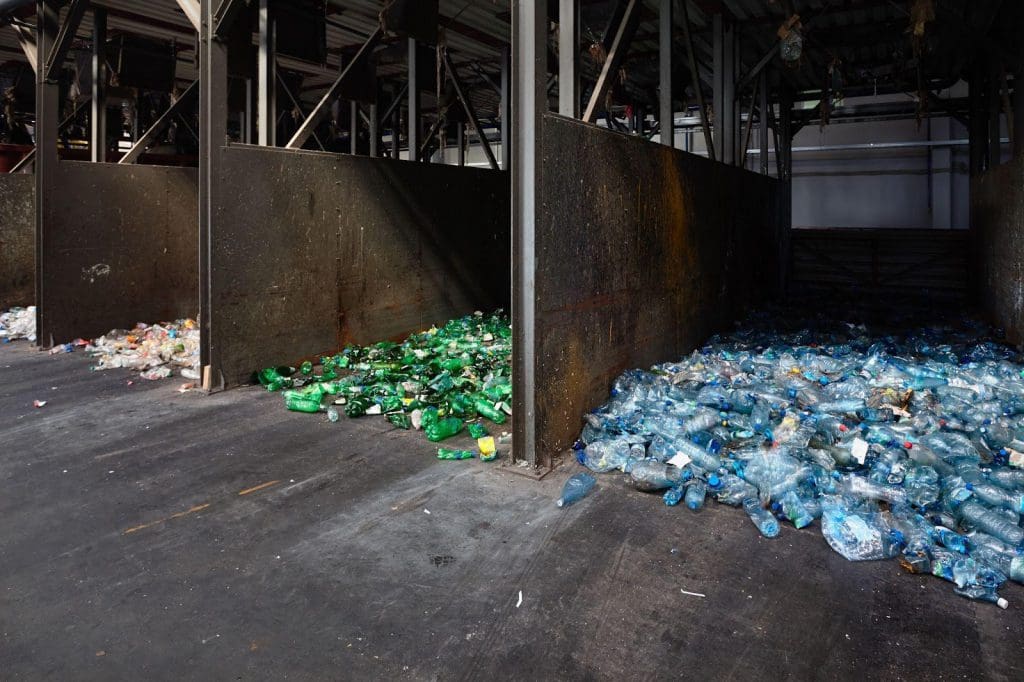

While the fate of most plastic lies in landfills and incinerators, uncollected litter accounts for 22% of all plastic waste—8 million tons of which enter our oceans yearly. For a visual context, imagine a garbage truck the size of New York City depositing its haul into the ocean every minute of every day for a whole year.

Plastic products have been estimated to last up to 500 years without breaking down, and, according to the OECD, only 9% of plastic is recycled annually. This is a tiny amount in comparison to other recyclable materials such as glass (25%), metals (35%), and paper (65%). About half of all plastic ends up in landfills, but there are undoubtedly better alternatives.

Burning plastic waste and harnessing the resultant energy may seem viable as an alternative to dumping. It reduces waste going into landfills and oceans, and the heat generated can produce steam for household power consumption, as an alternative to raw fossil fuels. However, about 10–15% of the total mass of burned plastic becomes toxic ash, released into the air we breathe.

These products in plastic ash can harm the environment and human health, as well as contribute to climate change factors.

We’ve all heard the advice to ‘reduce, reuse, recycle’ our plastics, but that places the onus on individuals, rather than industries. With recycling infrastructure still lacking in many regions, mass production of biodegradable or compostable plastics sounds like the best alternative. However, biodegradable products are still not well regulated, and the term ‘biodegradable’ isn't very well defined.

Biodegradable plastics can be made from both renewable biological materials and from fossil fuels. Under appropriate conditions, these can be broken down via enzymes and microbes to turn large polymers into much smaller molecules like methane, carbon dioxide, and water. Only about one percent of total plastics manufactured are biodegradable or bio based.

One misconception is that biodegradable plastics are the same as bioplastics. This is untrue. Made from plant-based materials rather than oil, bioplastics are seen as a renewable alternative to traditional plastic. One of the biggest contenders is polylactic acid, or PLA, which can be made from corn or sugar cane. However, PLA can still build up in landfills if not properly disposed of. It can decompose within three months under industrial composting conditions, but in a traditional landfill could still take anywhere from 100 to 1000 years, similar to traditional plastics.

Traditional mechanical recycling sounds like it should be very simple, but, in reality, it is costly and time-consuming for little overall gain. Plastic products can be melted down to be reconstituted, but they must be cleaned thoroughly and sorted by polymer type beforehand.

Besides the logistical issues, another problem posed by mechanical recycling is that the final product is rarely as good as its constituents. Each cycle of melting and remoulding can cause imperfections and weaknesses in the final product, allowing only a few uses before it finally has to be discarded.

While burning plastic waste is technically a kind of chemical conversion, new developments have found ways to recover more than just thermal energy.

Catalytic and pyrolytic chemical recycling can break up the long polymer chains of plastics into monomers (single units from which polymers are formed) and recover these into new polymers or other chemicals entirely. This is different from melting plastic down into pellets and remoulding them into usable products. Reforming polymers at a molecular level allows impurities to be ignored and high-quality products to result from the process over and over again.

The costs and practicalities of chemical plastic recycling at a properly industrial scale are not yet fully known, but perhaps the plastic problem is on its way to being solved for good. Let’s hope so!

Concerned about the fate of your chemicals? We are here to help. At Chemwatch we have a range of experts spanning all chemical management fields, from chemical storage to Risk Assessment to heat mapping, eLearning and more. Contact us today to find out more at sa***@*******ch.net.

Sources: